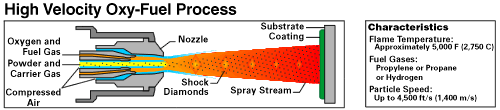

The high internal pressure combustion of a fuel, such as hydrogen, propylene or propane with oxygen, is the energy source in the HVOF spray process. The temperature is lower than in the case of plasma (3000ºC instead of 10000ºC), but particles velocity, when they meet the substrate is much higher (1100 m/s). HVOF coatings are very dense, hard and adhere very well to the substrate.

HVOF is ideal for developing carbide thermal spray coatings against wear, due to the relatively lower, compared to plasma, flame temperature.

Common carbides, sprayed by PyroGenesis, include:

- WC-Co

- Cr3C2—NiCr

- Cr3C2—NiCr—Mo

- TiC