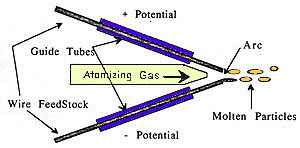

In this process, an electric arc melts two electrically opposite charged wires as they touch. As the wires touch, an electric arc is formed melting the wire feed stock. The molten particles are sprayed in a high-velocity air stream. Flame temperature can exceed 5000°C. It is a particularly efficient and productive technique. WA coatings are applied against wear and corrosion, as well as for the restoration of worn parts.

Metallic and cored wires are used for Wire Arc coatings.

- Fe—Cr based

- NiCr

- C 276 (against corrosion)

- C 22 (against corrosion)

- PD—101, PD—102 (against erosion and corrosion)

- Al

- Cu

- Fe—based cored with carbide materials (e.g. WC-Co, Cr3C2 etc.)